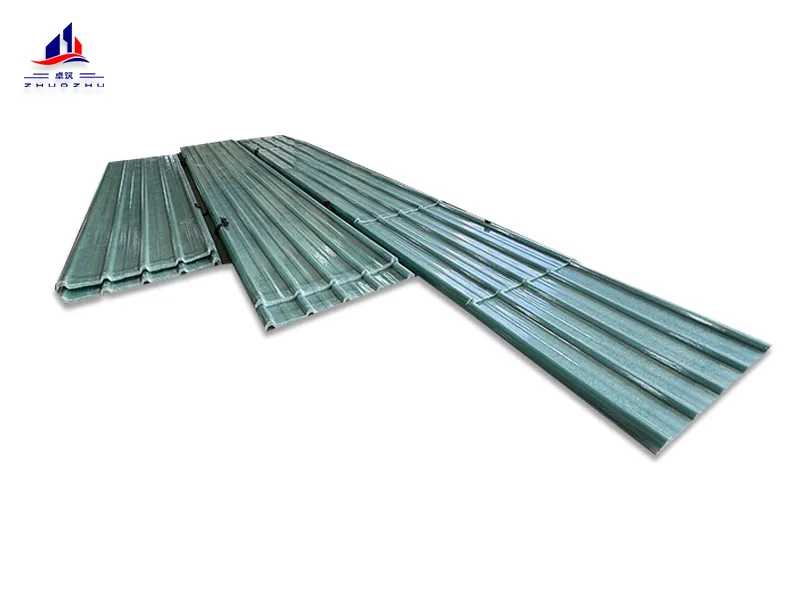

PVC Hollow Roofing Sheet

- Thickness: 10mm (customizable)

- Standard Length: 2m - 12m (customizable)

- Actual Width: 960mm/930mm/885mm

- Effective Width: 870mm/870mm/830mm

- Wave Pitch: 217.5mm/217.5mm/166mm

- Wave Height: 40mm/40mm/40mm

YOUR RELIABLE MANUFACTURER AND SUPPLIER OF HEAT INSULATION HOLLOW ROOF PANELS FROM CHINA

ZHUOZHU is a professional manufacturer and supplier of insulated hollow roofing panels in China. Through innovative multi-cavity structural design and high-performance polymer materials, we provide roofing solutions with superior insulation performance and structural reliability. Our products utilize unique air-insulated technology to significantly reduce the thermal conductivity coefficient, while maintaining lightweight characteristics and ease of installation. They are suitable for various energy-saving building projects, including industrial plants, commercial buildings, and high-end residences. We insist on end-to-end quality control from raw materials to finished products, equipped with customized production capabilities and a global supply chain, committed to providing customers with durable, energy-efficient roofing systems, safeguarding the energy future of every building with our “Made in China” quality commitment.

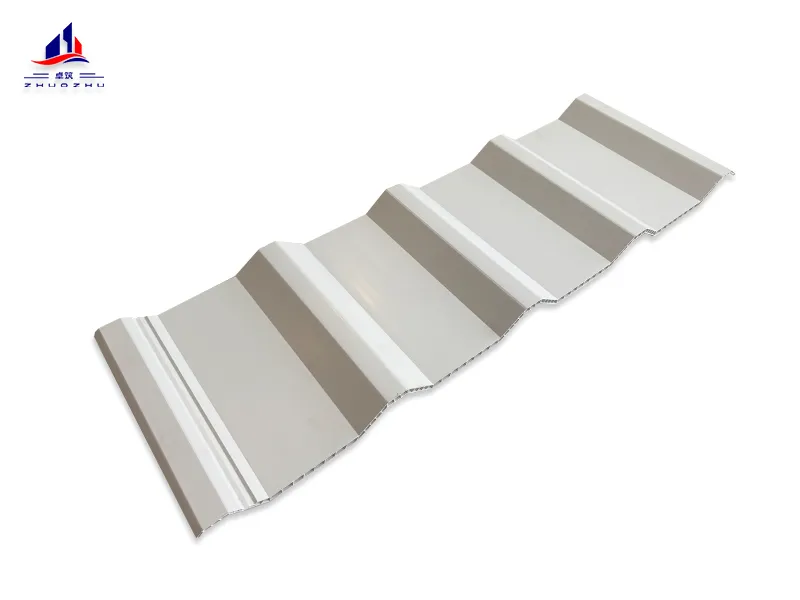

PVC Roof Panels

Hollow Roofing Sheet

1. Superior Thermal Insulation Performance

Featuring a multi-layer air cavity structural design, the thermal conductivity coefficient is as low as 0.18–0.22 W/(m·K). This blocks over 85% of solar radiant heat in summer and reduces indoor heat loss by 60% in winter, effectively lowering building energy consumption by 40%–50%.

2. Lightweight and High-Strength Structural Characteristics

With a density of only 20% of traditional concrete tiles (approximately 4.2–5.8 kg/m²) and a flexural strength exceeding 18 MPa, it achieves structural lightweighting while maintaining excellent load-bearing capacity, reducing the required roofing support structure by 30%.

3. Efficient Rainwater Drainage System

Equipped with a patented drainage channel design and a multi-tiered drainage pathway, it enables rapid layered drainage of rainwater on the roof. Its wind pressure resistance reaches over 3.5 kPa, and it has passed simulated tests for extreme weather conditions equivalent to 100-year rainstorms, ensuring reliable waterproofing under severe conditions.

4. Acoustic Noise Reduction and Environmental Adaptability

The multi-layer cavity structure reduces external noise by 28–35 decibels. Made from specially formulated materials, it withstands temperature fluctuations from -40°C to 120°C, achieves a UV aging resistance rating of Level 8, and offers a service life of over 30 years.

CONTACT US

Top PVC & FRP Roof Sheet Manufacturers/Suppliers from China

Hollow Roofing Sheets: An Integrated Solution for Energy Efficiency and Structural Innovation in Modern Construction

Technological Evolution: From Traditional Materials to Multifunctional Systems

Hollow roofing sheets represent a significant innovation in 21st-century building materials, marking a technological leap from single-function coverage to multifunctional integration in roofing systems. Unlike conventional solid materials, these multi-chamber composite panels fundamentally transform roof performance while redefining building envelope standards. With global energy efficiency requirements intensifying and green building concepts gaining widespread adoption, hollow roofing sheets are rapidly advancing across industrial, commercial, and high-end residential sectors through their unique technical advantages.

Convergence of Material Science and Structural Design Innovation

Multi-Layer Composite Structure Technology

Modern hollow roofing sheets utilize a sophisticated three-layer composite design:

External Protective Layer: 0.8–1.2 mm thick ASA or polycarbonate material providing UV protection and mechanical durability

Intermediate Cavity Layer: 6–12 independent air chambers forming stable thermal barriers

Internal Functional Layer: Integrated anti-condensation coating with reinforcement rib structure

Thermal Performance Optimization Mechanism

Through computational fluid dynamics-optimized chamber configuration, the system achieves:

92% air convection suppression efficiency

78%–85% radiant heat reflectance

8–10 hour thermal lag period

Seasonal heat transfer coefficient (U-value) stabilized at 0.20 ± 0.02 W/(m²·K)

Engineering Analysis of Six Core Technical Advantages

1. Breakthrough Thermal Performance

Hollow roofing sheets attain thermal resistance values of R-5.6/m²·K—7–8 times superior to traditional concrete roofing. Field applications demonstrate:

Summer surface temperature reductions of 28–35°C

Winter heat loss reduction of 60%–65%

Overall building HVAC load reduction of 30%–40%

Annual energy savings equivalent to 2,800–3,500 kWh per 100 m² roof area

2. Lightweight Structural Efficiency

At only 15%–20% the density of traditional materials yet achieving 18–22 MPa flexural strength, these sheets deliver multi-dimensional value:

Roof dead load reduced to 35–50 kg/m² (versus 200–240 kg/m² for concrete)

Primary steel structure requirements decreased by 25%–30%

Foundation costs reduced by 18%–22%

Ideal for building retrofits without structural reinforcement needs

3. Intelligent Drainage and Climate Adaptation

The bionic-inspired three-dimensional drainage system features:

180 L/(min·m) drainage capacity per unit width

ASTM E1592-certified wind uplift resistance to 200 km/h

Compliance with DIN EN 13859-1 heavy rain standards

Self-cleaning surfaces reducing 5-year maintenance by 80%

4. Acoustic and Environmental Optimization

Laboratory validation confirms:

38 dB average sound insulation (125–4,000 Hz frequency range)

Rain noise reduction to 28–32 dB(A)

Material linear expansion coefficient of 7.2 × 10⁻⁶/K

QUV accelerated aging test compliance (3,000 hours, ΔE < 2.0)

5. Industrialized Installation and Lifecycle Economics

Modular design enables:

120–180 m² daily installation per work crew

65% reduction in connection hardware

On-site waste controlled below 3%

70% lower maintenance costs over 30-year lifecycle

6. Sustainability and Circular Economy Contributions

Environmental performance metrics include:

96% material recyclability rate

65% lower production energy versus traditional materials

60% reduced transportation carbon emissions

92% photovoltaic integration efficiency for BIPV applications

Engineering Applications and Performance Validation

Industrial Facility Implementation: Automotive Manufacturing Complex

Project Scale: 45,000 m² roofing system

Technical Solution: Double-layer hollow sheets with integrated photovoltaics

Documented Outcomes:

4.8°C average summer temperature reduction

42% annual cooling energy reduction

380,000 kWh annual photovoltaic generation

4.2-year investment payback period

Commercial Retrofit: Regional Shopping Center

Challenge: Structural load limitations in existing construction

Solution: Lightweight hollow sheets replacing conventional materials

Verified Results:

180-ton roof load reduction

¥850,000 structural reinforcement savings

Indoor thermal comfort PMV index optimized to ±0.5

12-point LEED Gold certification contribution

Technical Standards and Quality Assurance

International Compliance Framework

Thermal Performance: ASTM C518, ISO 8990

Structural Performance: EN 1013, JIS A 6902

Durability: ASTM G154, ISO 4892-3

Fire Safety: EN 13501-1, GB 8624 Class B1

Quality Management Protocols

100% raw material batch certification

18 critical process control points

32-point finished product inspection

Third-party validation per 5,000 m² production

Installation Technology and Construction Specifications

Standardized Installation Methodology

Phase 1: Substrate Preparation - Purlin alignment verification (±3 mm/2 m tolerance) - Weather barrier integrity assessment - Mounting hardware positioning Phase 2: Primary Installation - Wind-direction optimized starting position - Precision fastener installation (8–10 N·m torque) - 150 mm minimum horizontal overlap Phase 3: Detailing Completion - Ridge joint sealing systems - Penetration perimeter waterproofing - Comprehensive system testing

Critical Technical Controls

Thermal expansion gaps: 2.5 mm/10 m (summer), 3.5 mm/10 m (winter)

Fastener spacing: Longitudinal ≤800 mm, transverse ≤1,500 mm

Sealant specification: Structural silicone with ±50% movement capability

Acceptance criteria: 2-hour full-system water testing

Maintenance and Performance Monitoring

Systematic Maintenance Framework

Quarterly: Connection integrity, sealant condition

Annual: Surface cleaning, drainage verification

Triennial: Thermal performance validation, structural assessment

Decadal: Comprehensive system evaluation and maintenance planning

Digital Monitoring Integration

Optional IoT systems provide:

Real-time thermal mapping (one sensor per 50 m²)

Structural stress monitoring

Drainage performance tracking

Cloud-based analytics and predictive maintenance

Future Technological Trajectories

Advanced Material Integration

Phase-change materials: 180 kJ/kg energy storage density

Thermoelectric conversion: 8%–12% efficiency

Photochromic adjustment: 30%–80% variable transparency

Self-healing surfaces: ≥85% micro-damage repair

Digital Manufacturing Advancements

Customized 3D printing production

Digital twin-guided installation

AI-optimized chamber geometries

Blockchain-enabled material traceability

Value Enhancement Assessment

Property value appreciation: 8%–12%

Insurance premium reduction: 15%–20%

Green certification contributions: 8–15 LEED/BREEAM points

Corporate ESG rating improvement

Industry Applications and Market Development

Strategic Implementation Areas

Advanced Manufacturing Facilities: Meeting stringent clean room and smart factory specifications

Data Center Construction: Resolving high-density thermal management challenges

Cold Chain Infrastructure: Achieving precise environmental control with energy efficiency

Urban Regeneration: Primary solution for existing building energy retrofits

Market Projections

Global Market Value: $8.5 billion by 2025

Annual Growth Rate: 12%–15%

Asia-Pacific Market Share: 45%–50%

Chinese Market Expansion: 18%–22% annual growth

Conclusion: Redefining Roofing System Performance Parameters

Hollow roofing sheets represent more than material innovation—they constitute a fundamental reimagining of building envelope technology. By resolving the inherent conflicts between energy efficiency, structural weight, durability, and economic feasibility in traditional systems, these advanced panels establish new benchmarks for integrated building performance.

As global construction embraces carbon neutrality objectives and sustainable building standards become normative, the technological superiority of hollow roofing sheets translates directly into competitive market advantage. For building owners, this represents strategic capital allocation toward lifecycle value optimization. For design professionals, it provides sophisticated tools for creating high-performance architectural solutions. For the broader industry, it catalyzes advancement across materials science, manufacturing technology, and construction methodology.

Selecting hollow roofing sheets signifies adopting systems-thinking to address building energy challenges, deploying innovative technologies to generate sustainable value, and applying professional expertise to create enduring architectural quality. Within the evolving paradigm of built environment responsibility, hollow roofing sheets will play an increasingly pivotal role in harmonizing architectural performance with environmental stewardship, establishing themselves as essential components in the sustainable buildings of tomorrow.

CUSTOM MANUFACTURER

A leading FRP & PVC roofing sheet manufacturer in China, dedicated to providing roofing system solutions, with over 20 years of outstanding manufacturing experience.

3

Advanced Manufacturing Facilities

36

103

103

Product Center

Explore our comprehensive roofing products, including 3 main collections and a variety of product finishes, designed to meet any need for modern building roofing.

GFRP Roof Sheet / Glass Fiber Roof Tile / Transparent FRP Roof Panel

This allows sunlight to be scattered multiple times, transforming the dazzling sunlight into soft light that illuminates a larger area.

UPVC Roof Sheet / PVC Roof Tile/ ASA UPVC Roof Panel

It will not change color for 10 years, is flame retardant, heat-insulating, corrosion-resistant, and low-temperature resistant.

Hollow Roofing Sheet / Hollow PVC Roof Tile / Hollow Roof Panel

Its hollow design gives it excellent heat insulation, ensuring a comfortable indoor temperature.

ZHUOZHU Blog

We aim to be your reliable information partner, consistently sharing practical blog articles, timely industry updates, and forward-looking new product information. With thoughtful content, we will accompany every step of your growth in the thermal insulation materials industry.