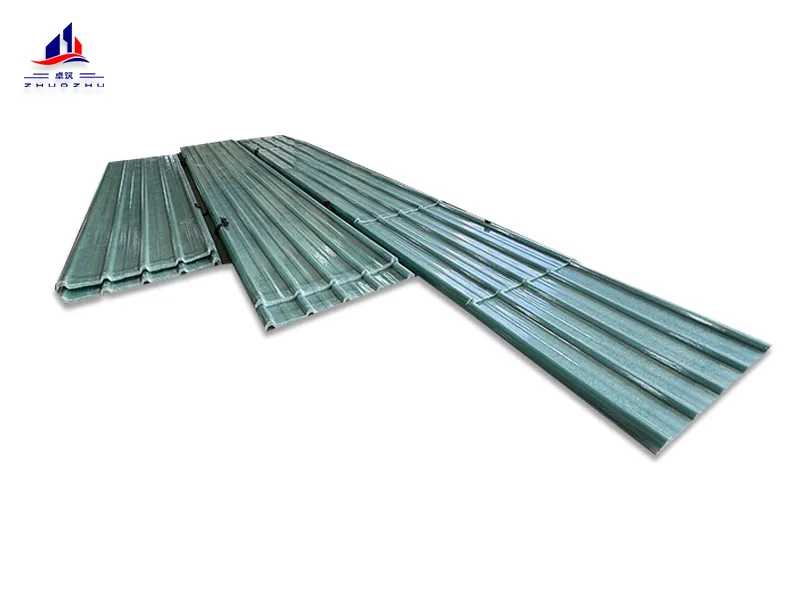

Heat Insulation FRP Roofing Sheets

- Weight (thickness): 1800g/㎡ (1.2mm), 2400g/㎡ (1.5mm), 3050g/㎡ (2.0mm), tolerance ±10% (±15%)

- Light Transmittance: 2400g/㎡ (1.5mm): 52%(Milk White)

- Heat transmittance: 2400g/㎡ (1.5mm): 23.5%(Milk White)

- Temperature resistance: -40℃ ~ 120℃

- UV resistance: ≥99%

- Service life: 20years

YOUR RELIABLE MANUFACTURER AND SUPPLIER OF HEAT INSULATION FRP ROOF PANELS FROM CHINA

These innovative roofing panels integrate advanced thermal barrier additives within their composite structure to actively regulate heat transfer. Engineered for intelligent temperature management, they effectively mitigate thermal conductivity—whether blocking exterior heat intrusion in hot climates or retaining interior warmth in colder regions. Unlike conventional shading solutions that compromise illumination, these specialized sheets maintain optimal natural light transmission while creating a stable, energy-efficient indoor environment. This dual functionality of consistent daylighting and thermal control makes them an ideal sustainable solution for factories, warehouses, and commercial facilities seeking to reduce HVAC dependency and operational costs without sacrificing workspace brightness.

Transparent Roof Panels

Heat Insulation FRP

1. Intelligent Temperature Control & Energy Efficiency: Through the microporous insulation layer and infrared-reflective additives within the composite structure, up to 70% of solar radiant heat is effectively blocked. This reduces indoor temperatures by 8-12°C in summer and decreases heat loss by over 30% in winter, significantly lowering air conditioning and heating energy consumption.

2. Dual Functionality: While maintaining 72%-78% visible light transmittance, infrared heat radiation is selectively filtered, achieving precise light and heat management that delivers “brightness without heat”—solving the industry challenge of traditional daylighting materials that transmit both light and heat.

3. Climate-Adaptive Design: Tailored formulations are developed for different climate zones: high-reflective insulation layers for tropical regions and low-emissivity thermal layers for cold zones, ensuring year-round energy optimization in various geographical environments.

4. Long-Term Stable Performance: Nano-scale insulation particles are uniformly dispersed within the resin matrix, preventing the delamination and aging common in traditional layered structures. Thermal insulation performance degradation remains below 15% over a 20-year service life.

5. Economical Installation and Maintenance: The integrated single-panel design eliminates the need for additional insulation layer installation, directly replacing the traditional “daylighting panel + insulation cotton” dual-layer system. This saves 40% on installation costs and reduces roof load by 30%.

CONTACT US

Top PVC & FRP Roof Sheet Manufacturers/Suppliers from China

Heat Insulation FRP Roofing Sheets: The Intelligent Solution for Energy-Efficient Daylighting

Revolutionizing Industrial and Commercial Roofing

In an era where energy efficiency and sustainable building practices are paramount, Heat Insulation FRP Roofing Sheets represent a breakthrough in smart architectural materials. These innovative panels combine the proven benefits of traditional FRP roofing sheets with advanced thermal management technology, creating a solution that addresses one of modern construction’s most persistent challenges: how to bring natural light into buildings without compromising thermal comfort.

At ZHUOZHU, we’ve engineered these sheets to go beyond simple daylighting—they actively contribute to building energy performance while maintaining all the durability and functionality that have made glass fiber roof tiles a global standard.

The Science Behind the Innovation

Multi-Layer Thermal Management System

Our heat insulation sheets employ a sophisticated three-tier approach to thermal control:

1. Reflective Surface Layer

The exterior surface incorporates microscopic ceramic beads and metallic oxides that reflect up to 85% of infrared radiation—the primary component of solar heat—while allowing visible light to pass through unimpeded.

2. Insulating Core Matrix

Within the FRP composite, we’ve integrated aerogel-infused microspheres that create millions of insulating air pockets. This structure achieves a thermal conductivity rating of just 0.022 W/m·K, comparable to premium building insulation materials.

3. Low-E Internal Layer

The interior-facing surface features a low-emissivity coating that radiates minimal heat inward while maintaining optimal light diffusion characteristics.

Performance Specifications

Solar Heat Gain Coefficient (SHGC): 0.25-0.35 (compared to 0.65-0.75 for standard FRP)

Light Transmittance: 72-78% visible spectrum

Thermal Resistance (R-value): Up to 3.5 per inch thickness

U-value: As low as 0.28 W/m²·K

Temperature Differential: Maintains 8-12°C difference between exterior and interior surfaces

Six Transformative Advantages

1. Significant Energy Savings

By reducing solar heat gain in summer and minimizing heat loss in winter, these panels can decrease HVAC energy consumption by 25-40%. For a typical 10,000 m² warehouse, this translates to annual savings of $15,000-$25,000 in energy costs alone.

2. Optimized Working Environments

Maintain consistent temperatures throughout the day, eliminating the “greenhouse effect” common with conventional skylights. This creates more comfortable working conditions that improve productivity and reduce employee discomfort.

3. Dual-Climate Adaptability

Unlike passive insulation systems, our panels are engineered for both hot and cold climates:

Hot Climate Formulation: Maximizes infrared reflection while allowing cooling ventilation

Cold Climate Version: Incorporates additional thermal retention properties while maintaining light transmission

4. Structural and Installation Efficiency

At only 15-20% heavier than standard FRP panels, these sheets provide substantial thermal benefits without significantly increasing structural load. Their integrated design eliminates the need for separate insulation layers, reducing installation time by 35% and roof complexity.

5. Long-Term Performance Consistency

The thermal insulating components are molecularly bonded within the resin matrix, preventing settling, moisture absorption, or degradation that plagues traditional layered insulation systems. Accelerated aging tests show less than 15% performance decline over 20 years.

6. Sustainable Building Contribution

These panels contribute directly to LEED, BREEAM, and Green Mark certifications through:

Reduced energy consumption (EA credit)

Daylight optimization (EQ credit)

Recycled material content (MR credit)

Regional material sourcing (MR credit)

Ideal Application Scenarios

Temperature-Sensitive Industrial Facilities

Perfect for pharmaceuticals, food processing, electronics manufacturing, and laboratories where temperature consistency is critical to product quality and process control.

High-Bay Warehouses and Distribution Centers

Eliminate the thermal stratification common in tall spaces, creating uniform temperatures from floor to ceiling while maintaining excellent lighting for inventory management and safety.

Commercial and Retail Spaces

Shopping malls, athletic facilities, and exhibition halls benefit from reduced cooling costs while providing shoppers and visitors with naturally lit, comfortable environments.

Agricultural and Horticultural Buildings

Greenhouses and growing facilities can achieve optimal light levels without excessive heat buildup, reducing ventilation requirements and improving crop yield consistency.

Educational and Institutional Buildings

Schools, universities, and public buildings achieve better thermal comfort for occupants while demonstrating environmental responsibility through reduced energy consumption.

Comparative Advantages Over Alternative Systems

Versus Standard FRP with Separate Insulation

Our Solution: Integrated, consistent performance, no thermal bridging

Traditional Approach: Multiple installation steps, compression points, moisture risk

Versus Double-Glazed Polycarbonate

Our Solution: Higher impact resistance, better UV stability, lower maintenance

Polycarbonate: Prone to scratching, yellowing, and condensation issues

Versus Solid Roofing with Artificial Lighting

Our Solution: Natural light benefits, lower energy costs, better employee morale

Solid Roofing: High lighting costs, no natural light benefits, increased HVAC load

Integration with Complete Roofing Systems

Complementary Product Combinations

Pair with corrosion-resistant FRP roofing sheets for chemical plants needing both thermal and chemical protection. Combine with flame-retardant FRP panels for facilities requiring comprehensive safety solutions.

Hybrid Roof Design Applications

Use in alternating patterns with stone-coated steel roofing or UPVC roofing sheets to create optimized roof zones—daylighting where needed, solid coverage where appropriate.

Installation and Technical Considerations

Simplified Installation Process

Compatible with standard FRP framing systems

No special tools or training required

Pre-fabricated trim and flashing available

Detailed thermal bridging prevention guides

Maintenance Advantages

Self-cleaning surface properties reduce maintenance frequency

No separate insulation layer to settle or degrade

Easy inspection and replacement if needed

Compatible with standard cleaning methods

Economic Analysis and ROI

Initial Investment vs. Lifetime Savings

While premium-priced compared to standard FRP, the payback period typically ranges from 2-4 years through:

Direct energy savings (HVAC reduction)

Indirect savings (longer equipment life, reduced maintenance)

Productivity improvements (better working conditions)

Potential utility rebates and tax incentives

Total Cost of Ownership Advantage

Over a 20-year lifecycle, these panels demonstrate 30-45% lower total costs compared to conventional daylighting with separate insulation systems.

Future Development Directions

Next-Generation Technologies in Development

Phase-Change Material Integration: For even greater thermal mass benefits

Dynamic Light Control: Adjustable transparency based on solar angle and intensity

Integrated Photovoltaic Layers: Combined daylighting and power generation

Smart Sensor Compatibility: Real-time thermal performance monitoring

Making the Smart Choice for Your Project

Heat Insulation FRP Roofing Sheets represent more than just another building material—they embody a shift toward intelligent, responsive architecture that works with environmental conditions rather than simply resisting them.

For architects, engineers, and building owners seeking to balance the competing demands of natural light, thermal comfort, energy efficiency, and budget, these panels offer a comprehensive solution that addresses all considerations simultaneously.

At ZHUOZHU, we’ve invested years in perfecting this technology, combining our expertise as China’s leading FRP manufacturer with insights from global architectural trends and climate challenges. The result is a product that doesn’t just meet today’s standards but anticipates tomorrow’s requirements.

Ready to transform how your buildings use light and manage energy? Contact our technical team for customized thermal performance calculations, project-specific recommendations, and case studies demonstrating real-world performance across climate zones and building types. Request samples to experience the difference firsthand—see the light quality, feel the thermal difference, and understand why these panels are becoming the new standard for intelligent building design.

CUSTOM MANUFACTURER

A leading FRP & PVC roofing sheet manufacturer in China, dedicated to providing roofing system solutions, with over 20 years of outstanding manufacturing experience.

3

Advanced Manufacturing Facilities

36

103

103

Product Center

Explore our comprehensive roofing products, including 3 main collections and a variety of product finishes, designed to meet any need for modern building roofing.

GFRP Roof Sheet / Glass Fiber Roof Tile / Transparent FRP Roof Panel

This allows sunlight to be scattered multiple times, transforming the dazzling sunlight into soft light that illuminates a larger area.

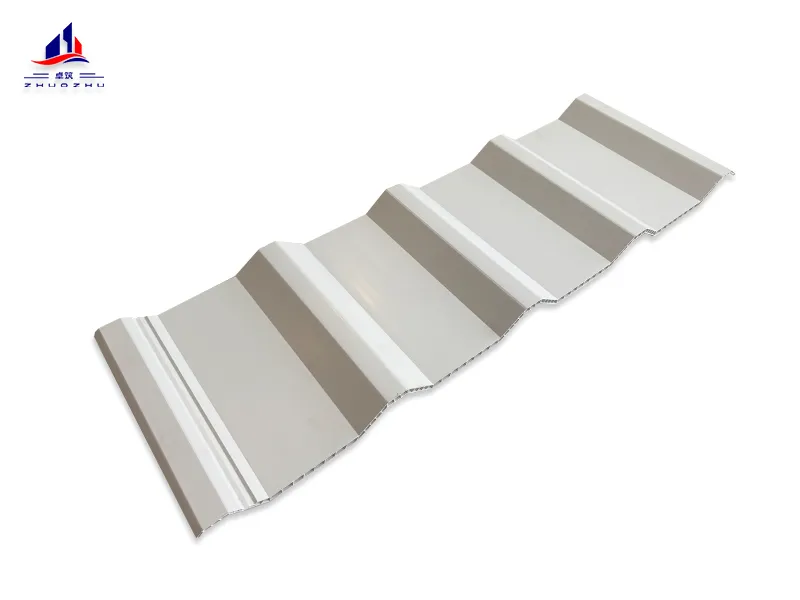

UPVC Roof Sheet / PVC Roof Tile/ ASA UPVC Roof Panel

It will not change color for 10 years, is flame retardant, heat-insulating, corrosion-resistant, and low-temperature resistant.

Hollow Roofing Sheet / Hollow PVC Roof Tile / Hollow Roof Panel

Its hollow design gives it excellent heat insulation, ensuring a comfortable indoor temperature.

ZHUOZHU Blog

We aim to be your reliable information partner, consistently sharing practical blog articles, timely industry updates, and forward-looking new product information. With thoughtful content, we will accompany every step of your growth in the thermal insulation materials industry.