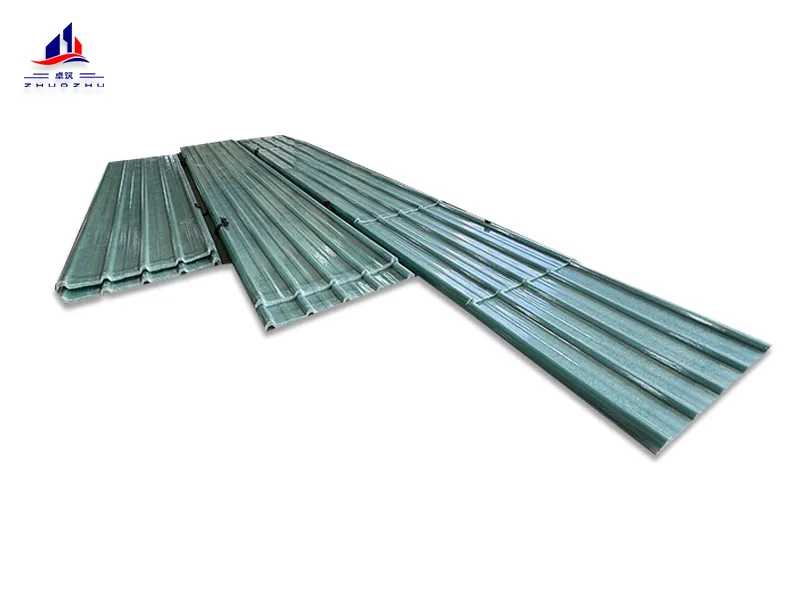

General Purpose FRP Roofing Sheets

- Weight (thickness): 1800g/㎡ (1.2mm), 2400g/㎡ (1.5mm), 3050g/㎡ (2.0mm), tolerance ±10% (±15%)

- Light Transmittance: 2400g/㎡ (1.5mm): 70%(Aqua Green)

- Heat transmittance: 2400g/㎡ (1.5mm): 66%(Aqua Green)

- Temperature resistance: -40℃ ~ 120℃

- UV resistance: ≥99%

- Service life: 15 years

YOUR RELIABLE MANUFACTURER AND SUPPLIER OF FIRE-RETARDANT FRP ROOF PANELS FROM CHINA

As the most widely used category in the FRP roofing industry, General Purpose FRP Roofing Sheets represent the optimal balance of performance, cost-effectiveness, and adaptability. These sheets are engineered to meet the fundamental requirements of most standard applications, providing reliable daylighting, durability, and weather resistance at an accessible price point. With a proven track record across countless installations worldwide, they offer a practical solution where specialized high-performance features are not required, making them the go-to choice for warehouses, manufacturing facilities, agricultural buildings, and commercial structures seeking straightforward, value-driven daylighting. Their standardized design ensures compatibility with common construction methods, while their consistent quality delivers dependable service life without unnecessary technical complexity or premium costs.

Transparent Roof Panels

General Purpose FRP

Optimal Balance of Cost and Performance: Utilizing standardized production processes and optimized formulations, these sheets ensure fundamental performance while achieving the best cost control, offering the most competitive unit price for large-scale applications. The comprehensive cost per unit area is 25%-40% lower compared to special-function models.

Broad Environmental Adaptability: The standardized weather-resistant formulation ensures stable performance within a temperature range of -30°C to 100°C. The surface UV-resistant coating provides ≥99% UV protection, making it suitable for basic construction needs in most climatic regions across the country.

Reliable Structural Performance Assurance: With a glass fiber content of ≥22% in the standard reinforced structure, combined with universal polyester resin systems such as G299C, the sheets achieve a tensile strength of over 82 MPa and a flexural strength of 125 MPa, fully meeting the load requirements of conventional industrial buildings.

Optimized Daylighting Efficiency: At the standard thickness of 1.5mm, the sheets achieve a light transmittance of 70%-72%. The professionally designed optical surface texture converts direct light into uniform diffused light, providing ample illumination while effectively avoiding glare issues.

Convenient Installation and Maintenance: Fully compatible with standard steel structure installation systems, the sheets can be cut and processed using conventional tools. The anti-static surface treatment ensures that daily maintenance only requires rainwater rinsing to maintain cleanliness, significantly reducing lifecycle maintenance costs.

Mature Supply Chain System: As a basic model, these sheets maintain stable annual production capacity, support quick delivery and flexible replenishment, ensure sufficient inventory depth to meet the schedule requirements of large projects, and come with complete supporting technical documentation and installation guidance systems.

CONTACT US

Top PVC & FRP Roof Sheet Manufacturers/Suppliers from China

General Purpose FRP Roofing Sheets: The Workhorse of Industrial Daylighting

Introduction: The Foundation of Modern Industrial Architecture

In the landscape of industrial and commercial construction, General Purpose FRP Roofing Sheets stand as the fundamental building block for daylighting solutions. These versatile panels represent the perfect equilibrium between performance and practicality, offering reliable illumination for countless applications without unnecessary complexity or premium costs. As the most widely specified category in the FRP market, these sheets have become the default choice for projects where straightforward, dependable daylighting is required.

At ZHUOZHU, we’ve refined our general purpose sheets through decades of manufacturing experience, creating products that deliver consistent performance across diverse applications while maintaining the accessibility that has made them an industry staple.

Core Technology and Construction

Balanced Material Composition

Our general purpose sheets employ a precisely engineered formulation:

Resin Matrix Optimization

We utilize specially formulated G299C/ET2139 grade unsaturated polyester resins that provide the ideal balance between mechanical strength, weather resistance, and cost-effectiveness. These resins offer:

125 MPa flexural strength

82 MPa tensile strength

92 MPa shear strength

1.40 g/cm³ density

Reinforcement Architecture

A minimum 22% glass fiber content from premium suppliers like OCV, JUSHI, and CPIC ensures structural integrity while maintaining optical clarity. The reinforcement pattern is optimized to distribute stresses evenly across the panel surface.

Surface Protection System

Every sheet features a 20-micron DuPont Melinex 301 protective film (or equivalent) that provides:

≥99% UV resistance

Anti-static properties for self-cleaning

Scratch and chemical resistance

Compliance with AS/NZS 4256 Parts 1&3:2006 standards

Key Performance Characteristics

Optical Excellence

Light Transmission: 70-72% at 1.5mm thickness

Light Diffusion: Professional optical surface treatment transforms harsh sunlight into soft, evenly distributed illumination

Glare Reduction: Eliminates harsh shadows and bright spots that can cause eye strain

Mechanical Reliability

Temperature Range: -40°C to +120°C operational capability

Thermal Expansion: 2.6 × 10⁻⁵ cm/cm/℃

Impact Resistance: Withstands standard industrial hail conditions

Wind Uplift: Engineered for standard wind load requirements

Longevity and Durability

Service Life: 20-year performance warranty

Color Stability: Resists yellowing and degradation

Maintenance: Virtually maintenance-free with natural rainwater cleaning

Six Compelling Advantages

1. Exceptional Value Proposition

General purpose sheets deliver approximately 85% of the performance of premium specialty sheets at just 60-70% of the cost. This makes them ideal for projects where budget constraints exist without compromising on fundamental quality requirements.

2. Universal Applicability

Designed to perform reliably in most temperate and subtropical climates, these sheets require no special environmental considerations. Their standardized formulation works effectively across:

Manufacturing facilities

Warehouses and logistics centers

Agricultural buildings

Commercial structures

Sports and recreational facilities

3. Proven Track Record

With millions of square meters installed globally, these sheets represent the most tested and validated FRP product category. Their performance characteristics are predictable and well-documented, reducing specification risk for architects and engineers.

4. Installation Simplicity

Compatible with all standard FRP installation systems, these sheets require no special tools, training, or accessories. Their predictable behavior during installation reduces labor costs and minimizes on-site errors.

5. Supply Chain Reliability

As our highest-volume product, general purpose sheets benefit from:

Consistent year-round production

Multiple manufacturing lines ensuring supply stability

Standardized packaging and handling

Immediate availability from regional stock

6. Technical Support Infrastructure

Complete documentation packages including:

Detailed technical data sheets

Installation manuals and videos

Structural calculation guidelines

Maintenance protocols

Regulatory compliance documentation

Typical Applications

Industrial Manufacturing Facilities

Provide consistent, high-quality daylighting for production areas, assembly lines, and quality control stations where accurate color rendering and uniform illumination are essential for productivity and safety.

Warehousing and Distribution Centers

Illuminate high-bay storage areas with natural light that reduces energy costs while improving inventory management accuracy and workplace safety.

Commercial and Retail Spaces

Create inviting, naturally-lit environments in shopping centers, showrooms, and service facilities where customer experience and energy efficiency are priorities.

Agricultural Buildings

Deliver optimal growing conditions in greenhouses, livestock facilities, and processing areas where balanced light distribution promotes plant and animal health.

Public and Institutional Buildings

Schools, community centers, and municipal buildings benefit from the combination of natural lighting, energy savings, and reduced maintenance requirements.

Performance Comparison Framework

Versus Premium FRP Products

While specialized sheets offer enhanced features for extreme conditions, general purpose sheets provide:

95% of the basic performance at 65-75% of the cost

Broader availability and faster delivery

Simplified specification and installation processes

Versus Alternative Daylighting Materials

Compared to polycarbonate, acrylic, or glass systems:

Superior impact resistance and durability

Lower maintenance requirements

Better fire performance characteristics

More consistent long-term performance

Integration with Other Roofing Systems

Complementary Role in Hybrid Roof Designs

General purpose sheets work seamlessly with other ZHUOZHU products:

Pair with heat insulation FRP sheets in mixed roofing applications

Combine with corrosion-resistant panels in facilities with varied environmental conditions

Interface with stone-coated steel roofing for architectural contrast and functional zoning

Transition and Interface Solutions

We provide complete detailing systems for:

Sheet-to-sheet connections

Perimeter and edge conditions

Penetration and skylight interfaces

Expansion joint treatments

Sustainability and Environmental Considerations

Energy Efficiency Contributions

Reduce artificial lighting requirements by 60-80% during daylight hours

Lower HVAC loads through intelligent placement and sizing

Contribute to LEED and BREEAM certification points

Environmental Responsibility

Manufactured with consideration for resource efficiency

Fully recyclable at end of service life

Low-VOC materials and processes

Energy-efficient manufacturing operations

Specification Guidelines

Thickness Selection Matrix

1.2mm (1800 g/m²): Light-duty applications, residential use, temporary structures

1.5mm (2400 g/m²): Standard industrial and commercial applications (recommended default)

2.0mm (3050 g/m²): Heavy-duty industrial, high-wind areas, extreme weather regions

Color Options and Performance

Natural/Translucent: Maximum light transmission (72%)

Opal/White: Balanced light diffusion (70%) with reduced glare

Tinted Options: Various colors available with corresponding light transmission adjustments

Economic Analysis

Lifecycle Cost Advantage

Over a 20-year service period, general purpose sheets demonstrate:

Lower initial investment than specialty products

Minimal maintenance costs

Consistent energy savings through daylight harvesting

No major replacement or refurbishment requirements

Return on Investment Calculation

Typical ROI periods range from 18-36 months based on:

Energy savings from reduced artificial lighting

Lower HVAC costs

Improved productivity in daylit spaces

Reduced maintenance expenditures

Installation Best Practices

Optimal Layout Strategies

North-facing orientation maximizes consistent, glare-free light

Strategic placement over work areas and traffic paths

Integration with artificial lighting control systems

Consideration of seasonal sun angles

Maintenance Protocol

Annual visual inspections

Occasional cleaning with mild detergent and water

Prompt attention to any physical damage

Regular inspection of sealing and flashing systems

Future Development Directions

While general purpose sheets represent a mature product category, continuous improvements include:

Enhanced surface coatings for improved self-cleaning

Slight weight reductions without compromising strength

Expanded color and texture options

Improved recyclability and circular economy features

Conclusion: The Reliable Foundation

General Purpose FRP Roofing Sheets may not feature the advanced technologies of specialized products, but their value lies in their proven reliability, accessibility, and versatility. They represent the sensible choice for projects where daylighting is required but extreme environmental conditions are not a concern.

At ZHUOZHU, we recognize that not every project requires premium features—sometimes what’s needed is simply a well-made, dependable product that does its job effectively day after day, year after year. That’s exactly what our general purpose sheets deliver.

For your next project requiring reliable, cost-effective daylighting, consider the proven solution that has served industries worldwide for decades. Contact our team for samples, specifications, and project references that demonstrate why these sheets remain the most popular choice in FRP roofing.

CUSTOM MANUFACTURER

A leading FRP & PVC roofing sheet manufacturer in China, dedicated to providing roofing system solutions, with over 20 years of outstanding manufacturing experience.

3

Advanced Manufacturing Facilities

36

103

103

Product Center

Explore our comprehensive roofing products, including 3 main collections and a variety of product finishes, designed to meet any need for modern building roofing.

GFRP Roof Sheet / Glass Fiber Roof Tile / Transparent FRP Roof Panel

This allows sunlight to be scattered multiple times, transforming the dazzling sunlight into soft light that illuminates a larger area.

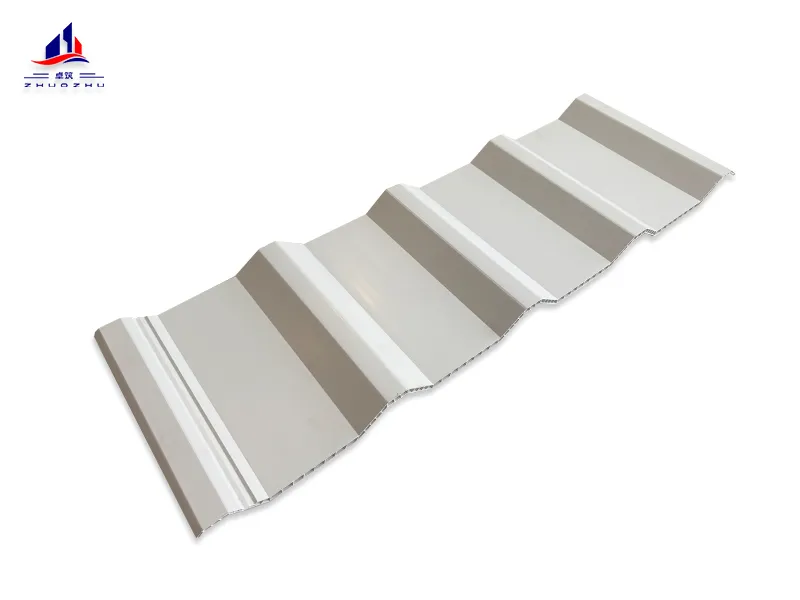

UPVC Roof Sheet / PVC Roof Tile/ ASA UPVC Roof Panel

It will not change color for 10 years, is flame retardant, heat-insulating, corrosion-resistant, and low-temperature resistant.

Hollow Roofing Sheet / Hollow PVC Roof Tile / Hollow Roof Panel

Its hollow design gives it excellent heat insulation, ensuring a comfortable indoor temperature.

ZHUOZHU Blog

We aim to be your reliable information partner, consistently sharing practical blog articles, timely industry updates, and forward-looking new product information. With thoughtful content, we will accompany every step of your growth in the thermal insulation materials industry.